A Practical Guide to Front Door Replacement: Materials, Costs, and Installation Tips

Outline:

– Why replace your front door: value, security, and comfort

– Materials compared: wood, fiberglass, steel, and hybrids

– Measuring, codes, and preparation

– Installation options: DIY vs. pro, step-by-step overview

– Conclusion: budgeting, maintenance, and decision framework

Why Replace Your Front Door: Value, Security, and Comfort

Your front door does more than open and close; it frames first impressions, guards what matters, and influences how your home feels in every season. Replacement often pays back in multiple ways. From a financial perspective, national resale analyses commonly show that quality entry door upgrades recoup a strong share of their cost at sale, with many markets reporting return-on-investment in the neighborhood of 60% to 75%, depending on material, design, and regional expectations. That financial signal pairs with daily benefits you can feel, like fewer drafts, quieter interiors, and a smoother, more reliable latch every time you head out.

Comfort and energy efficiency are closely linked to how a door seals and insulates. Older units may have warped slabs, tired weatherstripping, and gaps at the threshold that invite outside air. Modern insulated doors—particularly those with foam-filled cores—can deliver thermal performance roughly equivalent to R-5 to R-7 depending on construction, while a typical solid wood slab often sits closer to R-2 to R-3. Add a tight, continuous weather seal and properly adjusted hinges and strikes, and you reduce infiltration that forces heating and cooling systems to work harder. For doors with glass, low-e insulated glazing helps control heat gain and loss while still welcoming natural light into the foyer.

Security improvements are another strong motivator. A new door allows you to combine stronger frames and jambs with upgraded hardware. Even without reconfiguring your entryway, simple reinforcements can raise the bar for forced entry. Consider small, high-impact adjustments that stretch value:

– Use 3-inch screws at hinges and strike plates to anchor hardware into structural framing

– Choose a robust deadbolt with a hardened strike and a reinforced latch area

– Add a wide-angle viewer or sidelight with tempered or laminated glass for visibility

Curb appeal ties it all together. A clean design, durable finish, and crisp alignment lift the whole facade—especially when paired with a painted or clad frame that resists weathering. If your current door sticks in humidity, rattles in winter winds, or looks tired despite fresh paint, replacement can be a practical upgrade. The combination of sound, energy, and safety performance—plus an everyday upgrade in how it feels to enter your home—makes a persuasive case for acting sooner rather than later.

Choosing Materials: Wood vs. Fiberglass vs. Steel (and Hybrids)

Material choice sets the tone for performance, maintenance, and cost. Each option carries trade-offs, and understanding them helps you select a door that fits your climate, design goals, and budget. Solid wood has enduring charm and can be repaired and refinished repeatedly. However, it’s more sensitive to moisture and sunlight, especially in exposed entries without a generous overhang. Expect to monitor finish condition and recoat as needed, particularly on darker stains that absorb more heat.

Fiberglass aims to deliver the look of wood with greater stability. Foam-filled cores lift thermal performance, molded skins resist dents, and realistic grain textures accept paint or stain. In many climates, fiberglass strikes a balance: durable in daily use, relatively low maintenance, and often lighter than heavy hardwood slabs. Steel, by contrast, is valued for impact resistance and a crisp, modern look. Today’s insulated steel doors use foam cores and composite thresholds to limit thermal bridging. While steel can dent and may need careful touch-ups to protect cut edges from corrosion, it holds up well when finished and maintained properly.

Hybrid solutions also deserve attention. Engineered or insulated-wood cores paired with composite edges minimize swelling; aluminum-clad or vinyl-wrapped frames reduce upkeep; and laminated or tempered glass options improve safety. For doors with lots of glass, insulated units with low-e coatings and warm-edge spacers can meaningfully reduce heat transfer and condensation potential. Consider how each construction addresses your site conditions:

– High sun and limited overhang: favor fiberglass or well-finished, stabilized wood with UV-conscious coatings

– Coastal or humid zones: look for corrosion-resistant components and composite frames

– Cold climates: prioritize insulated cores, tight weatherstripping, and quality thresholds

Cost ranges vary widely by region and design complexity, but some general guidance helps anchor expectations. Basic insulated steel prehung units can start in the lower hundreds, while standard fiberglass often ranges higher due to molded skins and added hardware options. Premium wood or custom designs, including intricate glasswork and oversized transoms, can reach several thousand or more, especially when factory finishing is included. Factor in hardware (handlesets, deadbolts, viewers), upgraded hinges, and finishing supplies if the door arrives unfinished. When comparing quotes, verify that pricing covers the full unit (slab, jambs, threshold), any needed sill pan or flashing, and disposal of the old door.

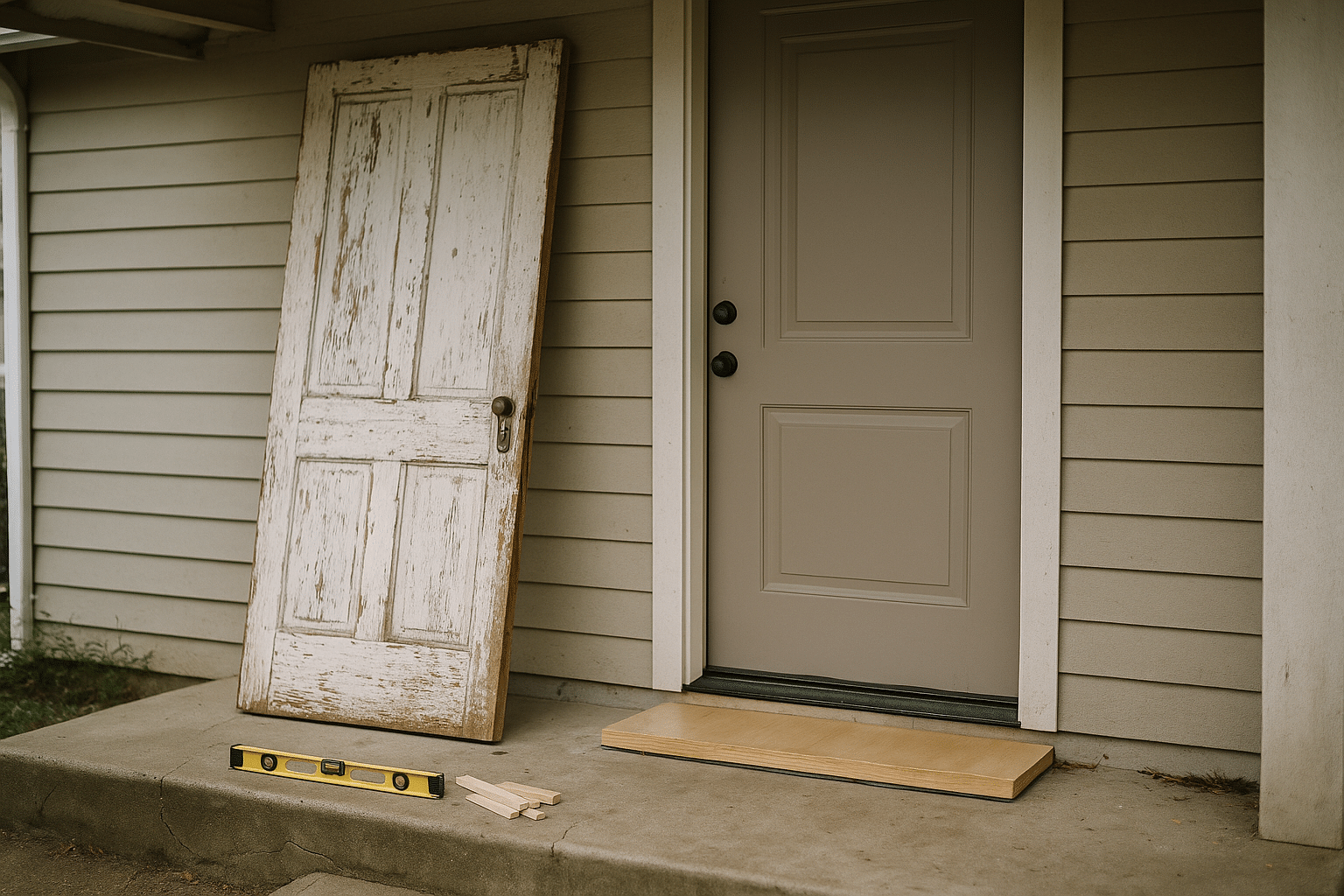

Measuring, Codes, and Preparation: Set the Stage for a Smooth Swap

Accurate measurements and a careful site check save time, money, and headaches. Start by confirming whether you’re replacing only the slab or the entire prehung unit. A full unit replacement delivers a fresh frame, new threshold, and factory-aligned weatherstripping—a strong choice when the old jamb is worn, out of square, or water-damaged. For a slab-only swap, the existing frame must be sound and true; misalignment can translate into sticky latches and uneven reveals that even skilled hinge shimming can’t fully hide.

Measure in three dimensions. Note the rough opening (framing-to-framing), the unit size (jamb exterior to exterior), and the slab size. Check height at both sides and the center, and width at the head, midspan, and sill. Document the swing and handing (which side the hinges are on as you pull the door toward you), jamb depth to match wall thickness, and threshold type. Identify potential obstacles: floor mats that lift the sweep too high, interior rugs that catch the swing, or doorbells and storm doors that need repositioning. Also inspect for water intrusion at the sill; staining, soft wood, or flaking subflooring often signal a need for a sill pan and repairs.

Local codes add another layer. Entries from an attached garage to the house typically require a self-closing, fire-rated door with a sealed threshold. Exterior doors may need specific safety glazing in or near the door, depending on glass size and placement. In energy-conscious jurisdictions, performance ratings for U-factor and air leakage can apply to new units. When in doubt, consult your building department—permits are straightforward in many areas and ensure inspections catch issues early.

Preparation sets you up for a predictable install day. Gather essentials in advance:

– Shims, construction screws, and a level long enough to span the jamb

– Low-expansion foam or backer rod and sealant rated for doors and windows

– Flashing tape, a preformed or site-built sill pan, and corrosion-resistant fasteners

Clear a staging area inside and out, protect floors, and schedule delivery when weather is cooperative. Overcast or mild days are ideal; heavy rain complicates flashing and finish work. On arrival, inspect the new unit for shipping damage, verify dimensions against your measurements, and pre-drill for hardware if needed. A measured, methodical start prevents surprises when the old door is off its hinges and the clock is ticking.

Installation Pathways: DIY Steps, Pro Workflow, and Avoiding Mistakes

Whether you install the door yourself or hire a professional depends on your comfort with carpentry, time constraints, and the condition of the opening. A prehung replacement is generally the most straightforward path for DIYers, as the factory aligns the slab, hinges, and weatherstripping. Still, precision matters—a small twist in the jamb or an out-of-level sill cascades into poor sealing, latch issues, and premature wear. Pros bring experience, specialized tools, and speed; in many regions, professional labor for a typical swap is a predictable line item, and warranty coverage may be clearer when a licensed installer handles the work.

If you’re considering DIY, a high-level sequence helps map the day. First, remove the old door and frame, carefully cutting caulk lines and extracting fasteners to limit wall damage. Dry-fit the new unit to confirm clearance. Next, install a sill pan—preformed or constructed from compatible flashing materials—and tape pan edges into the weather-resistive barrier. Set the new unit on the pan, check the hinge side for plumb, and fasten through the jamb at hinge locations, shimming behind each screw to prevent bowing. Adjust the head and latch side to create even reveals, check that the door swings freely, and confirm the latch catches without pressure.

Once the frame is true, insulate the gap with low-expansion foam or backer rod to avoid jamb distortion. Seal exterior joints with compatible sealant, integrate flashing tape at the head, and reconnect trim. Inside, verify alignment, recheck the sweep and threshold, and tune hardware. Finishing steps include touch-up painting or staining and caulk lines that transition neatly to siding and interior casing. Common oversights to avoid:

– Skipping the sill pan or improper flashing that invites water into the subfloor

– Over-foaming the jamb, which warps reveals and binds the latch

– Ignoring hinge screw length, leaving hardware anchored only to the jamb rather than framing

Hiring a pro? Ask for a scope that includes removal and disposal, sill pan installation, flashing integration, foam insulation, hardware installation, and finish caulking. Confirm lead times for custom sizes, glass configurations, and factory finishes. A clear proposal upfront—plus photos of similar completed entries—sets expectations and keeps the project on schedule.

Conclusion: Budget, Maintenance, and a Clear Decision Framework

Bringing your plan together starts with a complete budget. Beyond the door unit itself, costs typically include hardware (handleset, deadbolt, viewer), paint or stain, sealants and foam, sill pan and flashing materials, and trim or casing repairs. If you’re hiring out, add labor and potential permit fees; if you’re DIY, set aside time for learning curves and a contingency for replacement fasteners or unexpected framing repairs. Roughly speaking, many homeowners find entry-level insulated steel units installed at approachable price points, mid-tier fiberglass at a moderate step up, and premium wood or custom assemblies commanding a higher but visually distinctive investment. Regional labor rates, exposure conditions, and design complexity can shift these ranges noticeably.

Maintenance affects lifetime value. Wood rewards care with a warm, timeless presence; plan periodic recoating and vigilant sealing of horizontal joints and end grain. Fiberglass generally asks less, though seals and sweeps still need seasonal checks. Steel’s paint film deserves prompt touch-ups at any scratches to prevent corrosion, especially near coastal air. A simple annual routine keeps performance high:

– Inspect weatherstripping for compression set and replace if it no longer rebounds

– Tighten hinge and strike screws; upgrade to longer fasteners where needed

– Clean and lubricate locks and latches; verify smooth operation and full throws

Security and comfort upgrades are easiest at replacement time. Consider reinforced strikes, heavy-duty hinges with security pins, and laminated glass in sidelights to resist impact. For energy and moisture control, pair a quality threshold with a continuous sweep, add a compatible sill pan, and use sealants suited to your cladding and climate. If your entry is highly exposed, a modest overhang or storm barrier can extend finish life and reduce sun load, regardless of material.

Finally, turn choice into action with a simple framework: define your priorities (appearance, maintenance level, and energy performance), match materials to climate and exposure, set a realistic budget with 10% to 15% contingency, and decide on DIY versus professional installation after a candid look at your opening’s condition. When your door closes cleanly, seals tightly, and welcomes you with a satisfying click, the daily payoff is unmistakable. Thoughtful planning and a material choice aligned with your home’s realities make front door replacement a practical upgrade that delivers value you see and feel—every time you come home.